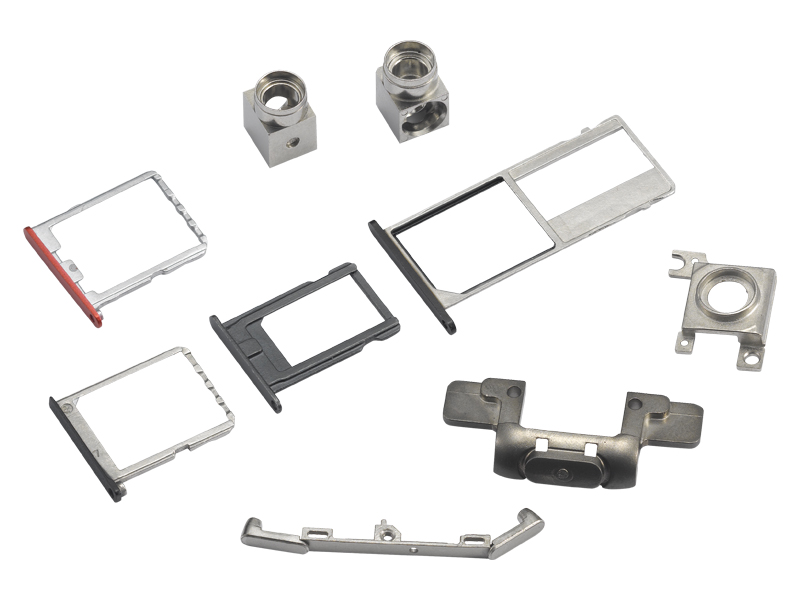

Metal powder injection molding (MIM) is a kind of net molding process suitable for producing products with small, three-dimensional complex shapes and special performance requirements. MIM has the characteristics of high-volume and high-efficiency molding of parts with complex shapes , so it is widely used in electronic 3C, automotive parts, medical instruments, industrial equipment and daily supplies.

In our country, smartphones, 3C products are the biggest field of MIM application. The rapid development of mobile phones, communications, and optical fiber industries has brought great opportunities for MIM. Some domestic MIM processing enterprises mainly produce MIM parts for smartphones and 3C products. Parts in these industries require high precision and strong durability. Commonly used products include, structural parts, connectors, special-shaped parts, mobile phone card holders, card slots, etc.

2. Auto parts

In Europe, MIM is the most widely used in auto parts manufacturers,while there are relatively few domestic MIM companies engaged in auto parts.

However, the potential of MIM in automobiles is great. Common applications include; ignition control lock parts, turbocharger rotors, valve guide rail parts, car brake parts, clutch inner rings, fork sleeves, Dispenser sleeves, automotive conduits, etc.

3. Industrial Machinery

The application of MIM in industrial equipment should not be underestimated. Its market is characterized by a large scale but dispersed applications. The application of MIM in industrial machinery includes micro motor parts, electronic parts, sensor devices, loose cotton machines, textile machines, sewing machines and other small complex parts of machinery.

4. Household and wearable products

A few years ago, MIM received a lot of attention in the manufacture of watch cases, watch chains, and watch connectors, especially in South China. Due to the impact of smart phones, the global watch market grew slowly and no longer received too much attention, but the basic market Still very large, the application of MIM in household appliances includes; watch case, watch chain, glasses arm, electric toothbrush, scissors, fan, golf head, imitation jewelry, knife head and other parts

5. OA office equipment

The applications of MIM in office equipment include: printer parts, magnetic cores, striker shaft pins, drive parts, etc.

6. Power tools

Electric tools also depend on MIM greatly. Considering that the machining of electric hand tool accessories is more complicated. The processing cost is high and the material utilization rate is low. In recent years, many applications have been developed. The products include special-shaped milling cutters, cutting tools, fasteners, micro-gear, loose cotton machine / textile machine / crimping machine parts, etc.

7. Medical products

In Europe and the United States, MIM has the largest application in medical component manufacturers, and China is the second largest medical device market in the world.

Moreover, MIM has great potential in the medical industry. Common applications include: gastroscope forceps, dental orthopedic frames, surgical forceps, scissors

Internal suturing needles, living tissue samplers, etc.