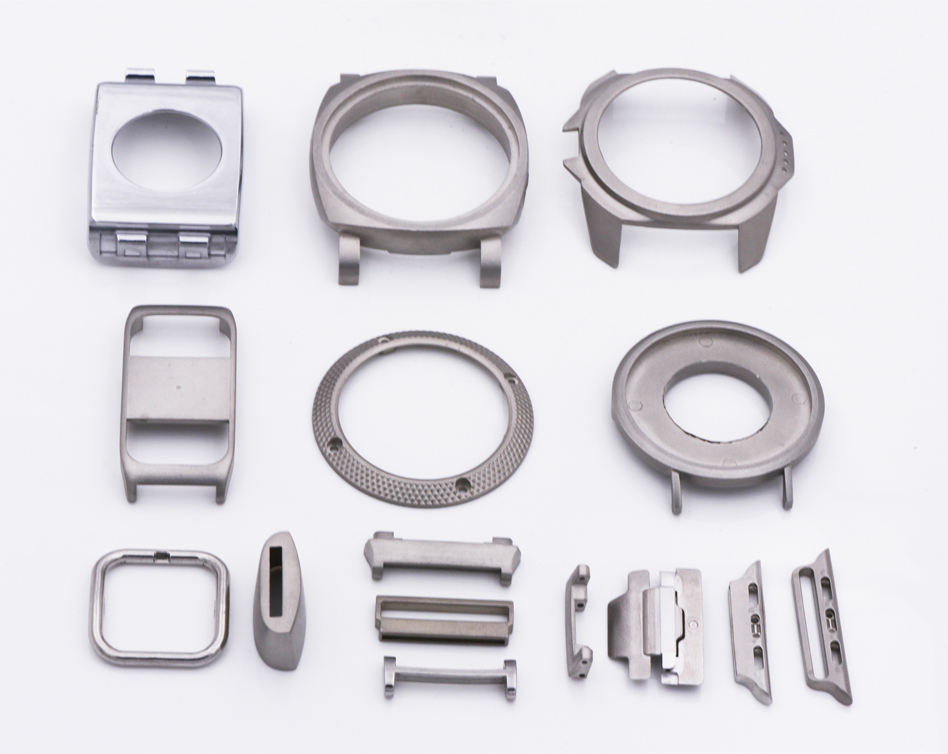

The specific process is as follows: First, making the powder fluid; Then injecting them into the mold; After, sintering the metal in the furnace; Finally, doing some processing to make them more precise.Some shaping and processing will be carried out if necessary. Like CNC processing, chemical parts processing, and forging. MIM is also a metal processing technology, which belongs to the metal material processing industry. (Picture 1 is the accessories of the watch industry)

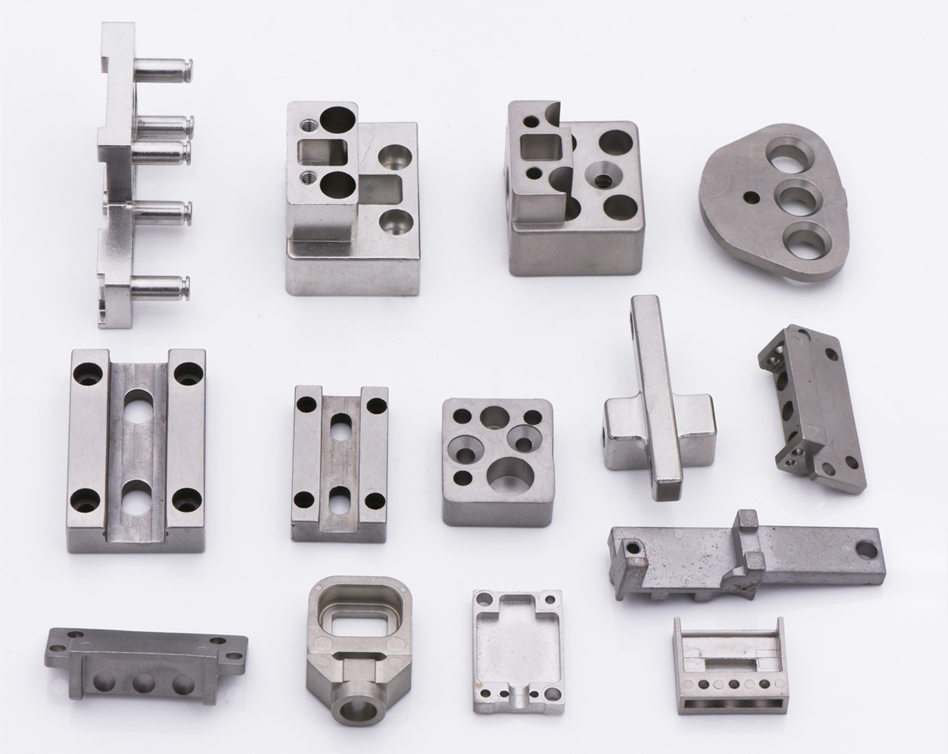

The advantages of the MIM process, First, the advantage of MIM is suitable to make some metal parts with very complex structures, very small sizes, and irregular shapes. Second, it can be applied to a wide range of raw materials, such as nickel-based alloy steel, stainless steel, tungsten alloy, and hard alloy. , titanium alloy, copper alloy and so on can be used in the MIM process. The third most important advantage is that it can be produced in large quantities. We are now making a component, and dozens of people can make hundreds of thousands to millions of parts a day, while the substrate and manpower occupied by the CNC process are very Many, unable to produce in such large quantities. (Picture 2 shows the products made by MIM process)

MIM process are mainly used in consumer electronics, automobiles, and medical devices. There are different main application fields in different regions; In China, it is mainly used in electronic products, Japan is mainly automobiles, Europe is also mainly automobiles, and in North America is mainly medical machinery and sports. At present, China is the country with the largest amount and sales volume. MIM industry has a history of just more than 20 years. It is an emerging technology, and more engineers in related fields need to learn the technology. We believe that as engineers in various fields learn more about the MIM industry, they are more familiar with the MIM process and its advantages. MIM will have greater applications in consumer electronics, automobiles, and medical fields