With the advancement of science and technology society, people pay more and more attention to health, energy-saving, and environmental protection, and the application prospect of metal injection molding technology on bicycles also increases.

At present, the economy of the bicycle industry is operating well, and output continues to grow steadily. The industry is highly specialized and the production system is becoming more and more perfect.

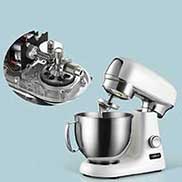

Using metal injection molding technology, the tiny bicycle parts can be designed as whole or multiple components, and the MIM process is used for one injection molding so that the parts can achieve the characteristics of miniature, integration, and low cost under the premise of satisfying performance. At the same time, parts with complex shapes such as external gears, cut grooves, external threads, cross holes, blind holes and grooves can be manufactured.